Background

Magellan Aerospace has rate increase demand on Airbus structural products. Some products affected by this increase in rate demand are the A320/A321 Inner rear spars.

CHALLENGE

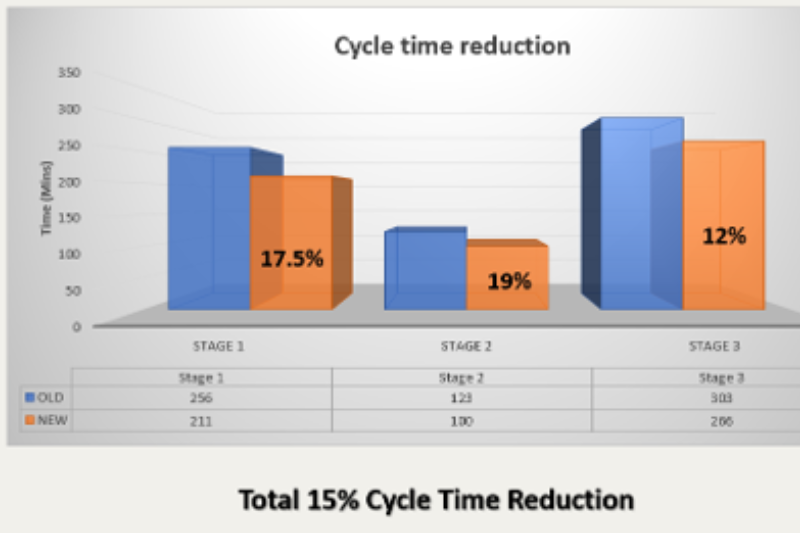

With a cycle time of 11 hours for one spar, the challenge was to reduce cycle time by 15 percent to help increase capacity within the manufacturing cell.

INNOVATION

This case study showcase how AMIC can provide support to a local manufacturer with engineering solutions using innovative software and hardware.

RESULT

The use of Catia V5 to reprogram the roughing strategy:

- Increased Maximum metal removal rate.

- Reduce the number of tooling used in roughing cycles.

- Better swarf evacuation, so no manual interventions.

The use of CG Tech Vericut force and Kistler Dynamometer:

- Balanced the forces on the cutting tool and optimized feed rates.

- Highlighted problems with machine tool A-Axis machine maintenance.

IMPACT

15 percent reduction in overall cycle time reduction gives the company the opportunity to increase capacity per machine tool.

Better swarf evacuation resulting in no manual intervention to clean the machine, while in cycle. Resulting in 100 percent efficiency of machine and operator.