Challenge

The UK food and drink manufacturing sector is facing a labor shortage with a vacancy rate of 5.0% in Q1 2024—significantly above the wider manufacturing (2.7%) and national (2.9%) averages.

This has also affected roles from engineers to operators, stalling productivity and limiting growth. Additionally, 47% of businesses are facing rising operational costs and regulatory pressures, further hindering workforce expansion.

INNOVATION

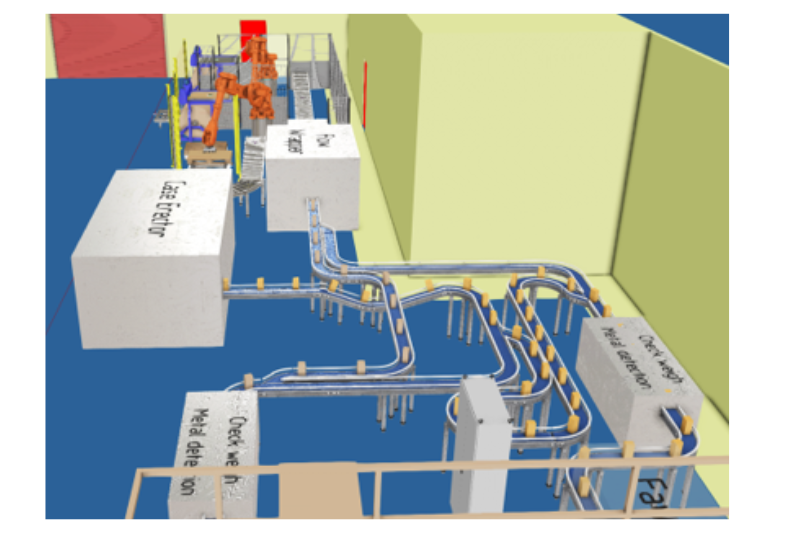

The pilot program engaged with 24 FMCG SMEs to implement advanced automation solutions, including high-speed robotic packing systems, custom palletizing, and virtual factory models.

RESULT

40% of participating industries either deployed the proposed solutions or reviewed their current practices , leading to enhanced productivity, reduced waste, and optimized workflows across various sectors like dairy, meat, and ready-to-eat meals.

IMPACT

Using Digital Manufacturing , virtual modelling ,and turnkey integration, our program provided technical insights to inform decision-making and streamline operations.

These tools enabled businesses to address skills shortages by empowering them to digitally validate complex workflows, optimize layouts, and automate high-risk tasks.

Industry feedback confirms that these capabilities have accelerated digital transformation, fostered resilience, and supported sustainable growth across the sector.